Apart from the excellent external finish, one of the great advantages of seam welded aluminium tube is the tight tolerance possible.

Consistent wall thickness along the full length of a tube is particularly important where tube must take some kind of insert, whether the insert be another smaller diameter tube, a tube with a swaged end, or a molded plastic part.

The uniform wall thickness offered by seam welded aluminium tube provides a consistent end to the tube regardless of where it may be cut along its length. End dimensions will always be the same within tight tolerances, and therefore always take the insert.

For the same reason seam welded tube lends itself readily to taking load bearing holes – such as for rivets, button clips or other fasteners. Because the walls of punched or drilled holes will be of uniform thickness, along the whole length of the tube, consistent performance for all holes can be relied upon.

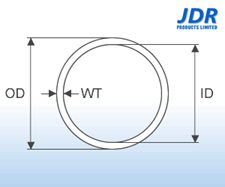

Typically seam welded aluminium tube can be specified as ‘OD x WT x Length’. Feel free to specify aluminium tube in combinations of Metric, Imperial and SWG. We’ll call you back to discuss alloy, temper and end use applications if it helps in getting the right specification.

If you’re not sure if your application requires seam welded, extruded or drawn aluminium tube, call us on 02476 326585 and we’ll be able to assist you.

Aluminium tube dimensions can be specified using outer diameter, wall thickness, and of course length.

JDR Products LTD Moreton House Whitacre Road Nuneaton CV11 6BW